The 5S system is the organization and rationalization of the workspace. The system appeared in the 80s in Japan, its creator is the Japanese Toyota Motor Corporation.

Five rules for the lean creation of a security service:

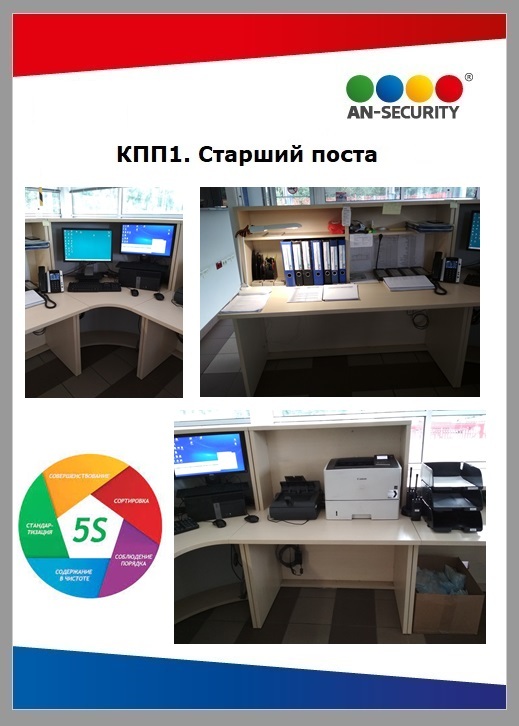

- Sorting and putting things in place: there should be only things necessary for work at the workplace;

- Strict order: things should be at hand, in their places and in sufficient quantity;

- Sustained cleanness: regular and frequent cleaning involves not only wiping surfaces from dust and garbage disposal, but also checking the serviceability of equipment;

- Standardization: visually informing employees about the first three principles;

- Stepping up: the system should become a culture of production, and not be a formality.

This method of lean resource management reduces losses, not costs, while maintaining and improving the quality of services. The approach also has a positive effect on labor productivity and employee motivation. Ultimately, all this is reflected in the growth of the competitiveness of AN-Security.